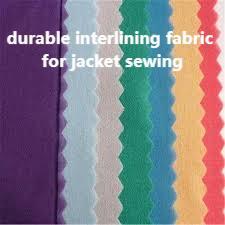

In modern tailoring, durable interlining fabric for jacket sewing serves as the hidden framework that transforms flimsy textiles into garments of lasting elegance.

The Role of Interlining in Garment Architecture

Every well-constructed jacket relies on an inner layer that provides shape and stability. Interlining sits discreetly between the lining and the outer shell, lending necessary support to collars, lapels, and front facings. Without this integral component, even premium outer materials like fine wool or cashmere would quickly lose their form, collapsing at stress points and creasing in unflattering ways. By reinforcing these critical areas, interlining preserves the intended silhouette and elevates overall attire quality.

Material Fiber Options and Performance

Interlining comes in a variety of fiber compositions—polyester blends, cotton, and even specialty heat-resistant yarns. Selecting durable interlining fabric for jacket sewing in the correct weight and composition ensures that the finished garment withstands the rigors of daily wear. Lightweight options keep unstructured jackets soft and breathable, while heavier variants deliver crisp, tailored lines ideal for formal blazers and overcoats. Understanding the interplay between fiber content and fabric weight enables precise customization for each design.

Brand Spotlight: Vlieseline’s Tailoring Innovations

Vlieseline has earned a reputation among professionals for consistent quality and ease of use. Their product lines include fusible and sew-in interlinings engineered for exceptional bonding strength and minimal bulk. Tailors appreciate Vlieseline’s breathable variations that allow moisture escape while preventing fabric puckering. Whether reinforcing denim jackets or crafting luxury evening wear, Vlieseline offers solutions that streamline production without compromising durability.

Application Techniques for Consistent Results

Mastery of interlining application is just as important as material selection. Fusible interlinings require controlled heat and pressure: too hot, and the lining seeps through; too cold, and adhesion fails. Sew-in types demand even stitch tension and appropriate stitch length to avoid puckers. Before full-scale production, testing on fabric scraps helps calibrate the iron temperature or sewing machine settings, ensuring uniform results across every piece. Meticulous integration yields smooth outer surfaces and crisp structural details.

Maintenance and Care for Extended Lifespan

A jacket’s longevity depends not only on construction but also on proper care. Always follow interlining manufacturer guidelines when laundering or dry-cleaning. Some fused interlinings can delaminate under excessive heat or aggressive solvents. Gentle pressing with protective cloths preserves bond integrity, while professional cleaning cycles maintain shape. Educating end-users on correct care routines enhances satisfaction and underscores the superior craftsmanship invested in each garment.

When tailors and manufacturers prioritize the synergy between outer fabrics and their inner supports, the result is a jacket that not only looks impeccable but endures season after season. Thoughtful material selection, precise application, and informed maintenance combine to deliver outerwear that stands the test of time.

interlining-factory.com